SECURITY GLASSES

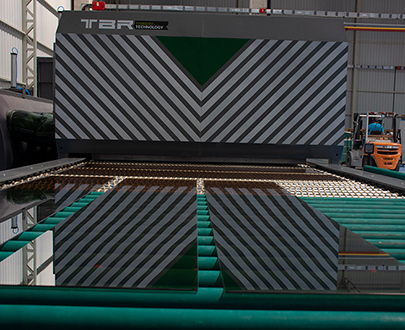

Tempered Glass

The tempering process includes heating and cooling stages to impart compressive stress to the outer surfaces of the glass on a horizontal line and an indirect tensile stress to the middle of the glass. Fully tempered glass is approximately 5 times more durable than untreated glass; It is suitable for use as safety glass as it shatters into dice-sized pieces when broken, reducing the risk of injury. Tempered glass is generally used in areas such as shower cabins, glass tables and coffee tables, glass railings and handrails, stall glass, white goods, doors, winter gardens, showcase glass, balcony glass.

Laminated Glass

Laminated glass is produced by joining two or more glass plates under heat and pressure with the help of colored or colorless special binder layers. It reduces the risk of injury by keeping the parts in place in case of breakage. Due to this feature, it is considered laminated safety glass. Laminated glass is also the right choice as it prevents or delays unwanted transitions from one side to the other. Lamination is a standard and typical solution for interior glazing of inclined or overhead glazing. Applications where Laminated Glass is generally used are the interior glass of double-glazed units, showcase glass, stair railings, windbreaks, interior partitions, sound insulation, and inclined or overhead glass applications.